Electric steelmelting plant, Kurakhovo, Donetsk Region

Construction of the enterprise began in 2006 and was completed in 2008 on the territory of the former plant of reinforced concrete structures. Currently, the metallurgical plant covers an area of 29 hectares.

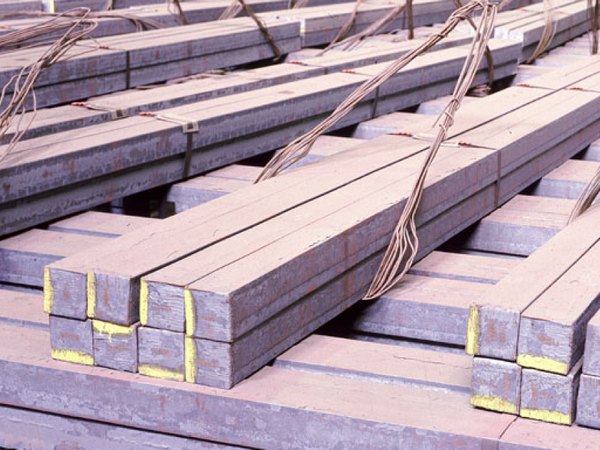

The project was developed by the Giprostal Institute (Kharkiv). The initial capacity was 287 thousand tons of square continuous billets per year, in 2012 it increased to 477 thousand tons after the modernization of the three-stream continuous billet machine.

In addition, the plant produces crushed stone-sand mixtures for road construction. The total investment in the construction project amounted to $ 80 million.

The main equipment was supplied by the Italian company STV: an electric arc furnace for 50 tons. a similar capacity installation of out-of-furnace processing of steel “oven-ladle” and caster.

The company is equipped with modern systems of gas treatment facilities and water treatment systems, developed in accordance with European environmental standards. The use of this equipment allows to minimize emissions into the atmosphere and completely eliminates the discharge of industrial water into the environment.

According to the results of ecological expertise conducted by the Donetsk Regional Department of Ecology and the Regional Sanitary and Epidemiological Station, the level of environmental impact is classified as “zero”, ie does not have a direct or indirect impact on nature.

The company has passed the certification audit of the integrated environmental management system ISO 14001: 2004.

The enterprise is affiliated with the Donetsk Metal Rolling Plant, before the start of hostilities in the Donbass it supplied the vast majority of billets for further production of rolled products.

In recent years, the Kurakhiv electric power plant has been operating at 17% of its design capacity. According to the results of 2019, production amounted to 84 thousand tons, in 2020 – also 84 thousand tons. The main reason is the difficulty in providing steel scrap, which is the raw material for the operation of the electric steel furnace.