There are only three technologies of steel smelting in the world: open-hearth, oxygen-converter and electric steelmaking.

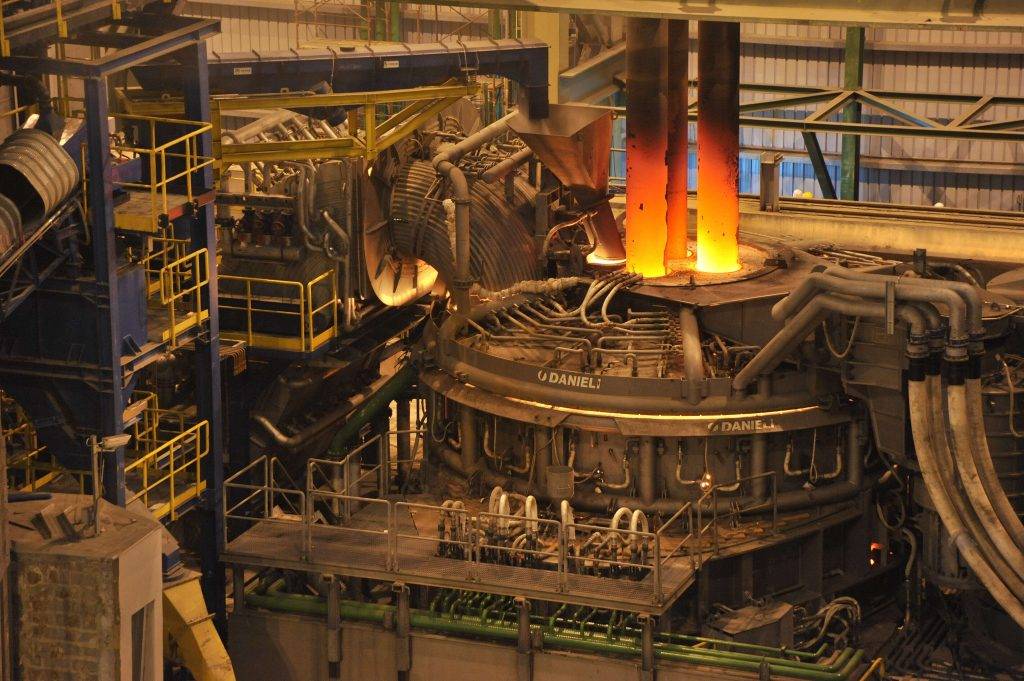

Electrometallurgy is a relatively modern method of steel production in contrast to open-hearth and oxygen-converter methods. In it the main raw material is scrap metal, which due to the electric arc in the furnace is melted into liquid steel.

Electric steel mills generate 10 times less CO2 emissions during operation.

Open-hearths have the highest level of CO2 emissions – an average of 2,500 kg per 1 ton of steel. Oxygen converter technology has emissions of approximately 1800-2000 kg of CO2 per ton of steel. Electrometallurgical technology – no more than 250 kg of CO2 per ton of steel.